Chinese | English

Product Center

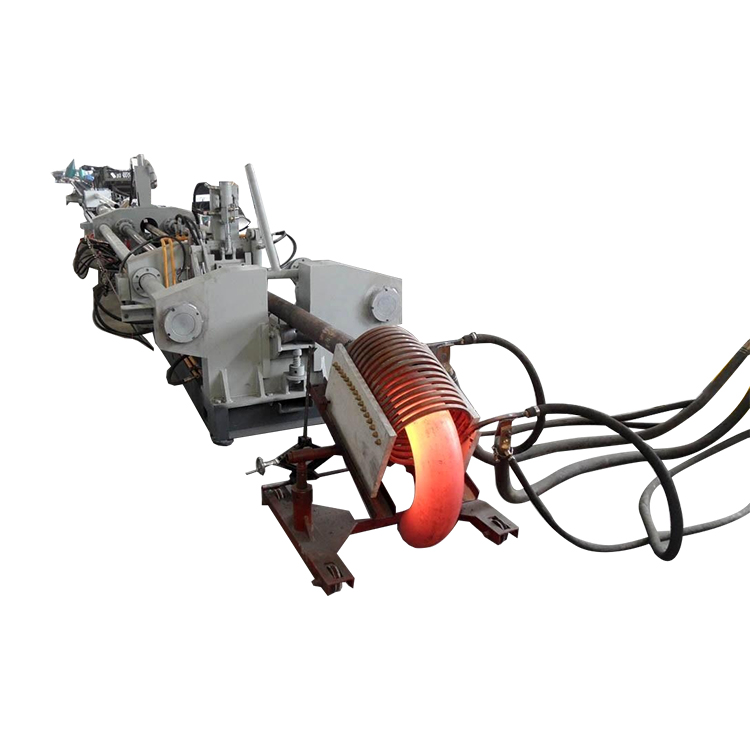

HOT FORMING ELBOW MACHINE

carbon steel elbow machine

Mechanical parameters

Technical parameters(307308)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

elbow machine

Elbow machine is the production of carbon steel elbow machine.Elbow machine is used for the formation of elbow, the main power is hydraulic cylinder, heating method is medium frequency heating (in addition, coal furnace and natural gas heating) elbow diameter from 21mm to 1620mm, wall thickness from 3mm to 120mm we can do

If you need stainless steel elbow, please choose the cold push elbow machine produced by our company.

The equipment mainly includes: machine stand, main oil cylinder support plate (including main oil cylinder), movable push plate, front support plate, semi-automatic feeding mechanism, intermediate frequency coil adjusting frame (including intermediate frequency heating coil), intermediate frequency power supply, electrical control system and so on.Chain elbow machine and other elbow machine series are non-standard products, there is no limited specification model, can be directly customized according to the needs of customers.In addition to elbow machines, pusher machines, hydraulic machines, Aocheng mechanical equipment Co., Ltd. also produces high quality and high efficiency pipe elbower, bevel machine, tee machine and other mechanical equipment and related pipe molds, welcome your order in the wind and rain.

Heat push elbow process is the advantage of medium frequency heating elbow machine: heat push elbow wall thickness unchanged.

According to the expansion and flow law of metal materials, the neutral layer of elbowing is translated to the outer arc of elbowing and the outer arc of elbowing has no plastic deformation through theoretical calculation and medium frequency induction heating pushing technology, and the wall thickness is not reduced during elbowing process of elbowing elbow.In other words, the thickness of the outer abdomen and inner abdominal wall is uniform after elbowing, which avoids the uneven phenomenon of the inner thickening and outer thinning during the deformation of the traditional tube elbowing process.Intermediate frequency elbow machine belong to the non-standard products, there is no specific limit specifications, can according to customers' special requirements directly, aoguang machinery co., LTD. Not only the production of cold elbow machine, intermediate frequency elbow machine drive system, and intermediate frequency pipe elbowing machine, cold extrusion machine, cold drawing tee thermoforming pipe-expanding machine and other mechanical equipment, equipment can meet the domestic and foreign market demand.

Related equipment