Chinese | English

Product Center

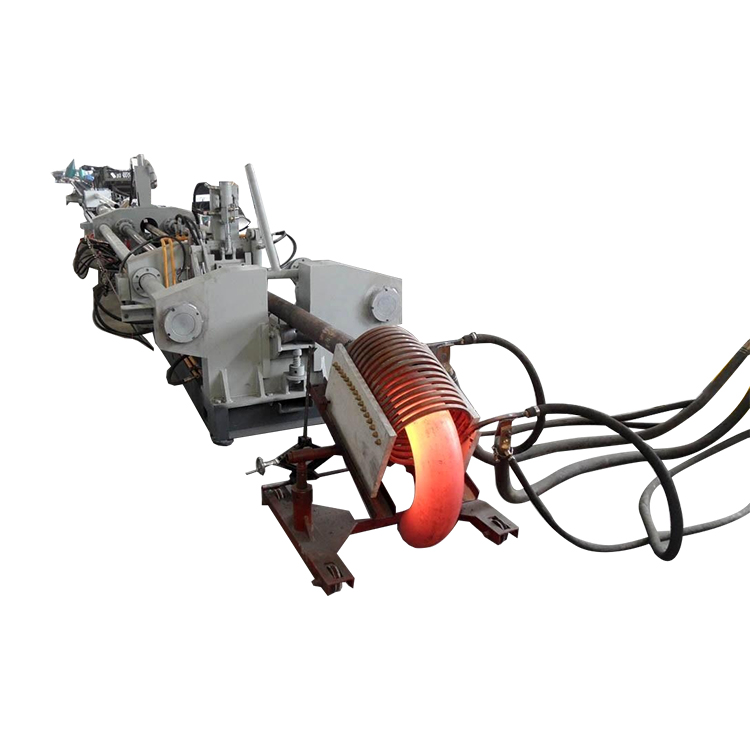

HOT FORMING ELBOW MACHINE

seamless elbowing machine

Mechanical parameters

Technical parameters(402403)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

seamless elbow machine

Intermediate frequency seamless elbow machine in the production of seamless elbow elbow forming process including the cutting the tube billet into core mold,with dedicated push the machine for continuous heating,hole diameter,forming process,such as hot push seamless elbow forming process with uniform wall thickness,good appearance and characteristics of sustainable production,has become the world numerous fittings factory in the production of carbon steel,alloy steel seamless elbow preferred process.

In addition to the inherent factors of the raw material seamless elbow steel tube itself,the main factors affecting the seamless elbowing quality are the geometric shape of the mandrel,the heating temperature and the diameter of the tube blank.Elbow is a kind of pipe fitting widely used in petroleum,chemical industry,power station,shipbuilding and many other industries. Its reliability is very important to the safe operation of the whole plant.

The reliability of elbow is determined by its strength,and the wall thickness is an important factor affecting the strength of elbow,and the key to ensure the wall thickness of hot-pushing elbow is to choose the suitable diameter of pipe blank.

The working principle of seamless elbowing machine push type: start the power supply of intermediate frequency elbow machine,stop the pushing head of pushing machine at the front limit,tighten the front clamp and loosen the back clamp.Put the blank tube into the feeding rack,use the feeding cylinder to feed the blank tube into the core rod and tighten the back clamp,loosen the front clamp,push the head back to the back limit,and tighten the front clamp to enter the pushing state.The mandrel is preheated to a certain temperature by induction ring (the mandrel temperature is measured by infrared thermometer),and then heated.

The equipment of the hot pressing INTERMEDIATE frequency elbow mainly includes: the frame,the main oil cylinder support plate (including the main oil cylinder),the movable push plate,the front support plate,the semi-automatic feeding mechanism,the intermediate frequency coil adjusting frame (including the intermediate frequency heating coil),the intermediate frequency power supply,the electrical control system and so on.

Related equipment