Chinese | English

Product Center

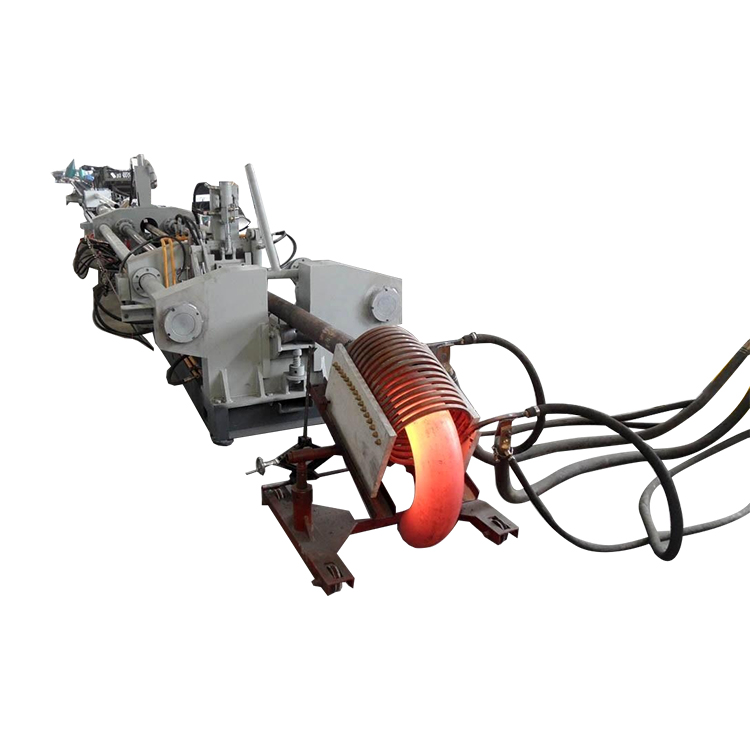

HOT FORMING ELBOW MACHINE

Basic machining principle of elbow machine

Mechanical parameters

Technical parameters(315401)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

Intermediate frequency elbow machine

Intermediate frequency elbow machine for elbow formation, the main power is hydraulic cylinder, heating mode is intermediate frequency heating (in addition to the use of coal furnace and natural gas heating).Elbow itself belongs to non-standard products, so there is no specific specifications and models, we can directly customize according to customer requirements.

We can make elbow diameter from 21mm to 1620mm and wall thickness from 3mm to 120mm.Intermediate frequency elbow machine is mainly used for bending carbon steel and alloy steel. If you need stainless steel elbow, please choose cold push elbow machine

Intermediate frequency elbow machine equipment mainly includes: machine stand, main oil cylinder support plate (including main oil cylinder), movable push plate, front support plate, semi-automatic feeding mechanism, intermediate frequency coil adjusting frame (including intermediate frequency heating coil), intermediate frequency power supply, electrical control system and so on.

Intermediate frequency elbow has the unique advantages of high geometric accuracy, uniform wall thickness, stable structure size, good mechanical performance and high productivity.

Basic machining principle of elbow machine:

It is based on a core head with certain geometry shape and size, namely ox horn core head as the mold, and a core rod of considerable length is welded in the rear part. The length of the core rod is determined by the length size and number of pieces of the push-tube blank in each working cycle.Before pushing, the blank tube to be pushed, which has been prepared in advance, is inserted into the core rod from the end of the core rod, and then sent over the push plate. During pushing, the push plate moves the blank slowly forward, and when the front end of the blank begins to enter the position of heating ring, it is heated immediately.At this point, the tube billet also begins thermoplastic deformation, that is, the bending deformation is generated, along with the expansion deformation. This deformation process continues until the elbow is completely separated from the core, and the elbow has been pushed into shape at this moment.

Related equipment