Chinese | English

Single head pipe beveling machine

Mechanical parameters

Mechanical video

Equipment details

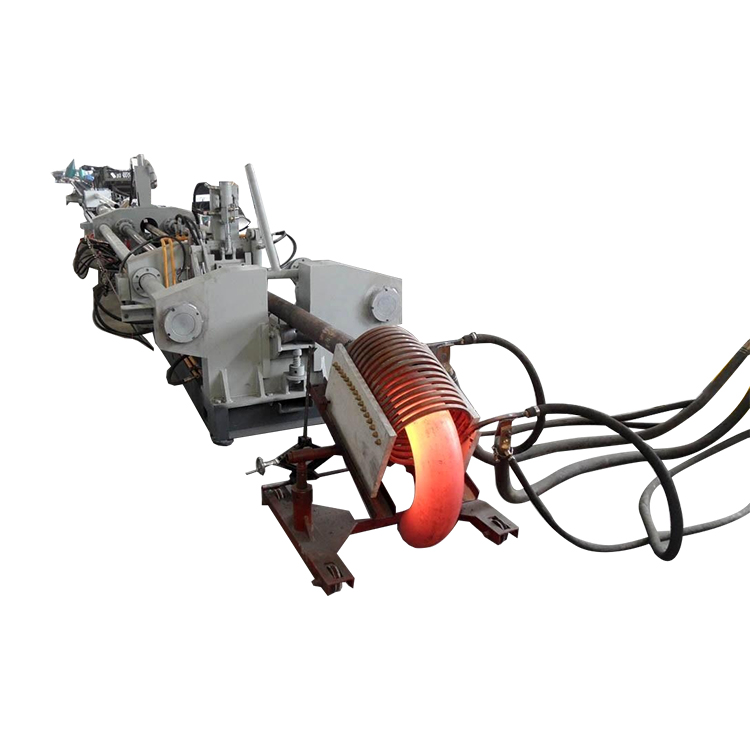

Single head pipe beveling machine

Single head pipe beveling machine is suitable for power plant, petroleum, chemical, shipbuilding and other industries, pipe fittings manufacturing units in use;Is fitting production and pipeline construction welding pipe beveling before processing of key equipment.

Single head pipe beveling machine can make different jig, can work from 820-1020 straight pipe and elbow pipe beveling;Angle of the knife dish with tool rest can be processing that is greater than 14 mm in wall thickness in the high pressure pipe wall thickness is less than 16 mm can be processed, floating head loss garden within 5 mm of low pressure pipeline;Adjust the position after the Angle head according to different pipe diameter by differential transmission by cutting processing;Clamping device USES the platform structure and flexible clamp can enlarge machining range and reducing pipe deformation;Pipe alignment using manually move around power head and jig platform electric lift up and down method;Centralized operation on the operation box machine tool by using the electric action, convenient and reliable.

Single head pipe beveling machine is composed of power head, cutter structure, the structure of the lathe bed, clamp platform structure, electrical control system and so on five big parts.

1, power head,

The power head by motor through the gear output sixth gear spindle speed and feeding speed of three kinds of differential head;Tail also is equipped with tool carrier electric quickly in a mechanism, can be used alone or with differential feed at the same time.

2, the knife dish

This knife plate can be installed on the tool rest Angle, should be according to the machining diameter size need to adjust the tool post corresponding position, before being cutting work, Angle cutting tool rest by differential speed transmission.

3, lathe bed institutions

Install electric bed body vertical feed mechanism, manual transverse cutting, lathe bed and dragging plate components, electric longitudinal feed is fast and the work into two types of speed, the two kinds of speed can work alone or synthetic or reverse at the same time.

4, clamp platform

Clamp mounts are installed on the platform and electric hoist, longitudinal and lateral T slot platforms have to install the pipe support and flexible clamping mechanism.

5, electrical control system

Special electrical components installed in the electric box, operating components installed in suspension control box, the action of machine tool can be operation on the operation box.