Chinese | English

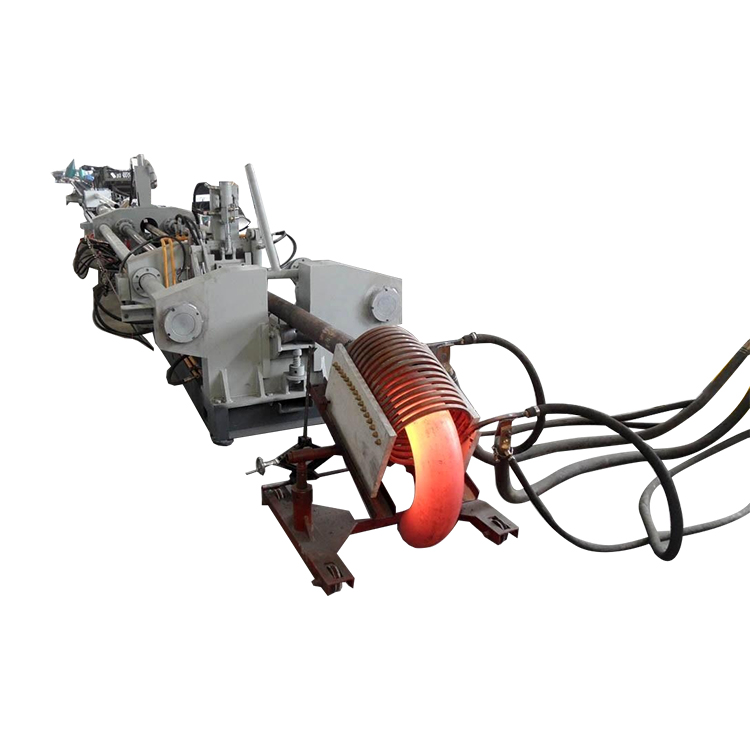

Hot forming pipe expanding machine

Mechanical parameters

processing range |

3”—12” |

8”—24” |

16”—30” |

20”—36” |

30”—48” |

|

Pipe thickness |

Sch80 |

||||

|

Max.pressure |

31.5MPa |

||||

|

Working pressure |

25 MPa |

||||

|

Working speed |

0—1000mm/min |

||||

|

Return speed |

1500—2000mm/min |

||||

|

Cylinder Diameter |

180*2 |

250mm*2 |

360mm*2 |

320mm*4 |

360mm*4 |

|

Cylinder stroke |

6500mm |

6500mm |

6500mm |

6500mm |

6500mm |

|

Cylinder thrust |

60T*2 |

120T*2 |

250T*2 |

200T*2 |

250T*4 |

|

Motor power |

22.5kw |

46kw |

48.5kw |

75kw |

100kw |

|

IF power supply required |

250kwa |

400kwa |

600kwa |

800kwa |

1000kwa |

Mechanical video

Equipment details

Our hot forming pipe expanding machine, mainly for domestic large diameter steel pipe production cannot meet the demand of market and all kinds of steel pipe specification is not complete, meet the needs of small batch more varieties of steel pipe production, can satisfy the different material steel pipe hole enlargement and various non-standard steel tube expanding needs, is currently the main production process of large diameter steel pipe.Is now widely used in military industry, power plant construction, aerospace and Marine industrial equipment manufacturing industry, for the country's steel pipe industry and made great contribution to energy construction.

The hot forming pipe expanding machine is applied in seamless steel pipe, straight seam welded pipe, coil pipe and other steel pipe thermal expanding production.Extension system of steel tube varieties are: all kinds of carbon steel, alloy steel, stainless steel, etc.

The patent product set cone die hole enlargement technology, medium frequency induction heating technology, hydraulic technology in one, with the reasonable technique, simple equipment structure, the construction of low energy consumption, low investment, good product quality, wide range of raw materials and products specifications suitability, flexible variable low input of production batch adaptability to replace the traditional steel pipe industry tension dial hole enlargement technology, became the resolve the shortage of large diameter seamless pipe at home and abroad, a series of large and medium diameter welded pipe specification is difficult to complete an important and indispensable production capacity.As energy by solid (coal), liquid (oil) to the gas (natural gas) the utilization and development of pipeline steel pipe demand and energy.Has formed a complete thermal expansion of steel tube processing industry.

Second, in recent years, with the user on the thermal expansion to improve the quality of steel pipe, our factory developed only for the equipment of expanding intelligent constant temperature system, to ensure the maximum thermal expansion of steel pipe quality.

Intelligent constant temperature characteristics:

1, the intelligent control of intermediate frequency power supply at the time of expanding production will steel tube heated to the required temperature and constant, especially in the thermal expansion of high alloy steel pipe, more can reflect the superiority of the system to adapt to the thermoplastic deformation temperature area narrow, effectively avoid the human factors caused by the alloy steel pipe burnt (high temperature) to produce the scrap quality decline and die for steel tube, at the same time avoid the low temperature and the thermal expansion unit thrust lever or die fracture is caused by the rising.Ensure the safety of the thermal expansion unit running, to eliminate the unsafe factors.

2, the intelligent thermostat system will medium frequency power supply with constant temperature heating one, thus ensuring thermal expansion pipe heating is always in a state of constant temperature, compared with the manual operation of steel pipe heating, energy conservation, environmental protection, simplify the operation procedures, reduce the labor costs, can achieve a operators at the same time monitoring the ten most normal production expansion tube expansion pipe unit, and can be through the pressure, velocity, temperature programming overload protection.On the expanding production due to the expansion pipe unit pressure is too high and the unsafe factors.Each unit set up two temperature measuring point intelligent automatic temperature control, according to the different type of preset steel pipe heating temperature, choice for expanding tube heating and constant temperature, and the real-time display and record, can print and save heating temperature parameters in real time curve and history curve.

3, the thermal expansion of steel pipe specifications: interchanged from 60 to 1420 mm in diameter, wall thickness 3 ~ 120 mm, the length of 3 ~ 24 m.Extension system of all kinds of steel pipe (such as T91 / P91-92-92, Q235, Q345, 45 #, A106B - C, 12 crmov).

4, hot forming pipe expanding machine mainly includes: frame, main oil cylinder plate (including the main oil cylinder), activity before pushing plate, plate, automatic feeding mechanism, feed roller, mold brackets, intermediate frequency coil to adjust (including intermediate frequency heating coil), intermediate frequency power supply, electric control system, etc.