Chinese | English

Product Center

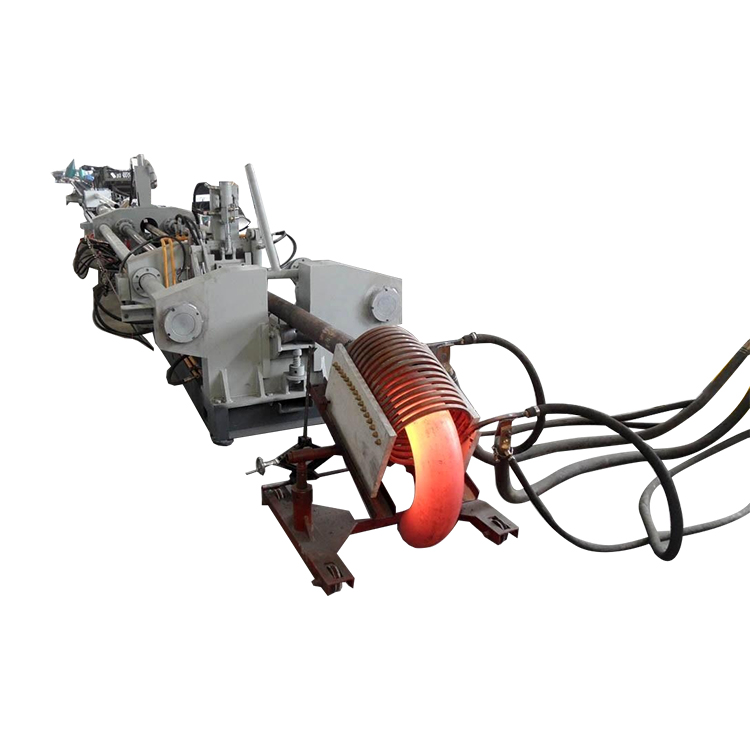

HOT FORMING ELBOW MACHINE

seamless elbow machine

Mechanical parameters

Technical parameters(408409)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

seamless elbow machine

Elbow manufacturing process: use a forklift to feed the shaped elbow into the shaping mold on the working table of the hydraulic press, complete the shaping of the elbow once, and use a forklift to remove the shaped elbow from the shaping mold.Then rough machining, machining or gas cutting method, cut off the elbow at both ends of the excess, and reserve 10~15mm groove machining allowance.This elbow machine is used for elbow formation, the main power is hydraulic cylinder, heating mode is medium frequency heating (in addition to the use of coal furnace and natural gas heating).

Elbow pushing machine itself belongs to non-standard products, so there is no specific specifications and models, we can directly customize according to customer requirements.We can make elbow diameter from 21mm to 1620mm and wall thickness from 3mm to 120mm.

The equipment of seamless elbow machine mainly includes: the frame, the main oil cylinder support plate (including the main oil cylinder), the movable push plate, the front support plate, the semi-automatic feeding mechanism, the intermediate frequency coil adjusting frame (including the intermediate frequency heating coil), the intermediate frequency power supply, the electrical control system and so on.

Elbow push machine working principle and process: it is by a horn shaped core or mandrel into the mold, pipe fitting into the mold, the mold should have two half arc, up and down each one, in the push process is a process along the mandrel bending.There is support at the back, and the charging pipe section is threaded into the mandrel, and there is a memorial arch at the back to fix the mandrel.There is a hydraulic rod jacking device in the middle, which pushes forward through the hydraulic transmission of the top column.Push the pipe along the semi-circular groove of the mold along the mandrel until the ceiling column reaches the end point. The limit switch is dead. Then push the pipe down to finish the processing.The outer diameter after shaping has reached the size requirement of the finished product.The wall thickness is controlled by the wall thickness of the incoming material.

In elbow push system machine drive system in the process of the bend, under normal circumstances wall thickness should not be changed, but if for tool reason, some local wall reduction happens, so generally refer to material, wall thickness to add some allowance, such as the elbow is 2.5 mm wall thickness, pipe of the 2.8 mm or so commonly, to prevent the push system error due to the local reduction of thickness.

Related equipment