Chinese | English

Product Center

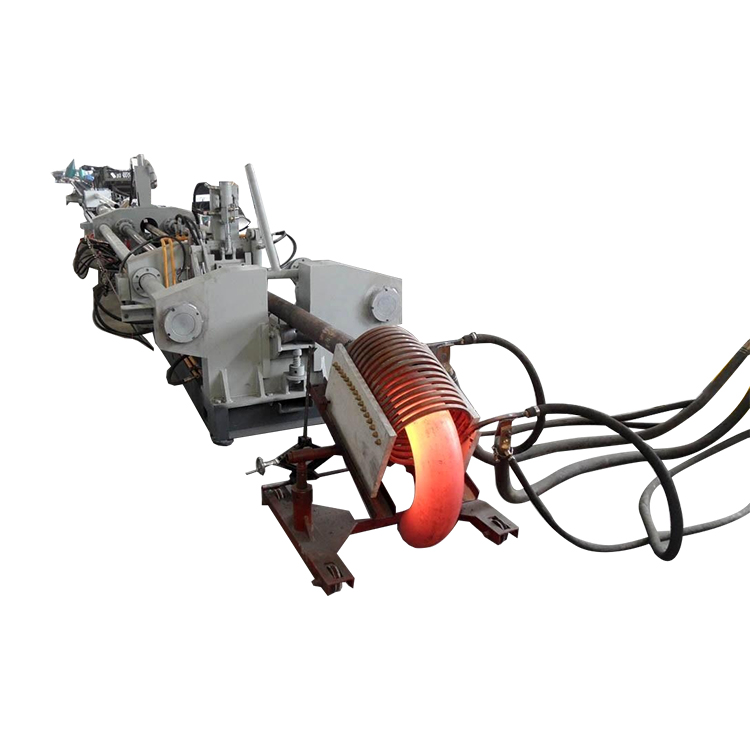

HOT FORMING ELBOW MACHINE

Hydraulic elbow pusher machine

Mechanical parameters

Technical parameters(412501)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

Hydraulic elbow pusher machine

Elbow, tee, size and head are all important pipe fittings in the hydraulic application, so elbow push machine as the production of elbow pipe fittings equipment, the customer is more high quality requirements, at this time, if elbow machine, cold push elbow machine is to buy elbow machine customers Gospel.

Working principle of elbow pusher:Push heat bend molding is according to the volume of the metal plastic deformation law of several tube billet in turn set on the mandrel, and then start the extrusion push system equipment, pipe, in turn, will push into the push bending mandrel, tube billet front-end sent to push at the beginning of bending mandrel and began forming process, as along the axis bending mandrel, push toward the exit end, gradually realizes the hole diameter and bending deformation, when the tail tube rounds from push bending mandrel exit, the bend forming is completed, push bending process with the increment of outside diameter, thrust the tube billet continuous radial compensation, therefore, finished product compared to the pipe wall thickness and bend without thinning,And the thickness of the outer and inner arc wall is basically the same.

Pipe fitting equipment such as elbow machine, pipe expanding machine and tee machine are very needed building materials in the pipe fitting machinery market at home and abroad. Our company is committed to improving the production efficiency of these machines and making them better serve the needs of customers.Elbow pushing machine adopts heating induction technology, strong technical, high production quality.

The equipment of the hydraulic elbow machine mainly includes: the frame, the main oil cylinder support plate (including the main oil cylinder), the movable push plate, the front support plate, the semi-automatic feeding mechanism, the intermediate frequency coil adjusting frame (including the intermediate frequency heating coil), the intermediate frequency power supply, the electrical control system and so on.

The equipment and the process method of bend machine belongs to elbow push system technology, the structure of the hydraulic bend machine main points: the central core head including transverse hollow cylinder structure, bending arc under the front of the hollow structure and the back end of the head and tail handle, tubular core end handle for cylindrical projection in central core end handle insert core rod front of hollow, head and tail handle core rod set on the outside of the core hole;An intermediate frequency heating coil is evenly arranged around the outer side of the cylinder structure and the arc structure along the extension direction of the core head.The technological method of elbow pushing includes the following steps: 1) Pipe fitting blanking;2) Lifting and fixing the push core head;3) The inner surface of pipe fitting blank shall be treated and coated with high-temperature lubricant;4) The pipe fitting blank is hoisted on the pushing tooling;5) Preheating of push core head;6) Start the oil pump and push the elbow under pressure;7) Push the elbow;8) Head alignment and shaping;9) Heat treatment.

Our company mainly produces hydraulic elbow machine, intermediate frequency elbow machine, tee machine, intermediate frequency pipe bender and other pipe fitting equipment and pipe fitting machinery.

Related equipment