Chinese | English

Product Center

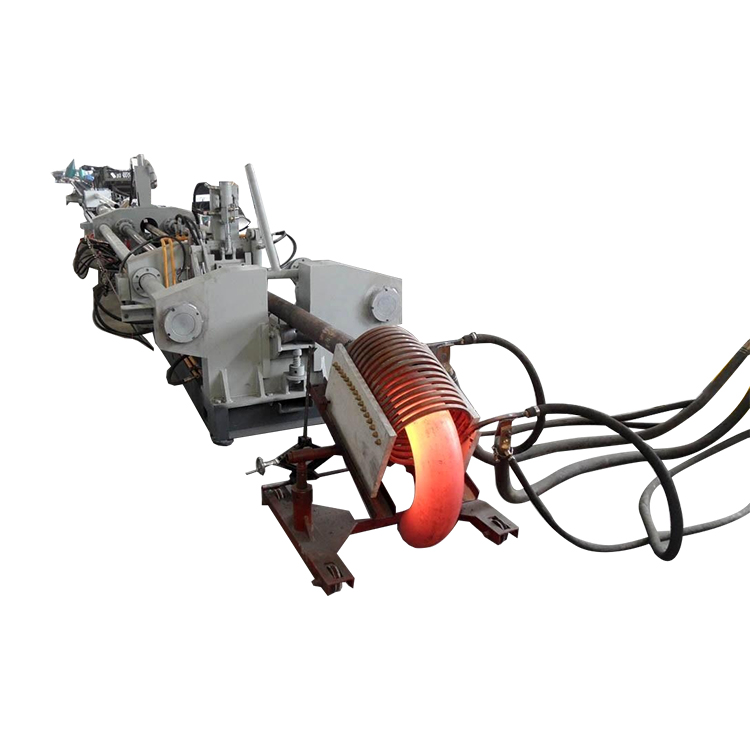

HOT FORMING ELBOW MACHINE

Elbow continuous forming machine

Mechanical parameters

Technical parameters(410411)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

Elbow continuous forming machine

Elbow continuous forming machine equipment mainly includes: machine stand, main oil cylinder support plate (including main oil cylinder), movable push plate, front support plate, semi-automatic feeding mechanism, intermediate frequency coil adjusting frame (including intermediate frequency heating coil), intermediate frequency power supply, electrical control system and so on.

Intermediate frequency bend motor as a process: the two pieces of blank tilt into the mould at the same time, the use of lower die before and after the location and the steps of the central, the lower die side lateral positioning of positioning plate, using the upper and lower die wall to short side bending, such a work schedule in the press, bending forming a workpiece two direction, do not need to pressure device.This structure can not only two workpiece at a time, and at the edge of the curved short when the lateral force can be offset each other, to avoid the adverse impact of the lateral force and tilted at the same time two blank of upper die and automatic guiding role, because the workpiece material is stainless steel, the bending springback tendency is bigger, so consider the measures to reduce springback when mould design, particular way is:The single surface clearance of the convex/concave die is equal to 4-4.4mm, and the forming die has a rebound quantity of 1°. The workpiece is pressed by the friction press, and the slider of the press touches two workpieces at the same time when descending to the lowest point. The workpiece is bent out of shape, and sufficient correction force is applied to ensure the bending accuracy of the workpiece.

Elbow machine equipment mainly includes: machine stand, main oil cylinder support plate (including main oil cylinder), movable push plate, front support plate, semi-automatic feeding mechanism, intermediate frequency coil adjusting frame (including intermediate frequency heating coil), intermediate frequency power supply, electrical control system and so on.

Elbow push molding machine, its features are: including the push automatic chuck, elbow forming mold, cutting saw head, cutting push slide table.The inner taper clamping flap of the automatic chuck locks the workpiece under the advance force of the outer locking sleeve and loosens the workpiece under the action of the reset spring.The forming mold includes the upper mold and the lower mold with the special machining cavity, and the material is high strength and wear resistant mold steel.The cutting device is installed on the slide table with high precision linear guide rail as guide pair, and is cut smoothly by the speed regulating hydraulic cylinder.By adopting the above scheme, the invention and innovation of a small elbow forming machine with high reliability and high production efficiency "elbow pipe fitting continuous push forming machine", hereinafter referred to as "elbow continuous forming machine"

Related equipment