Chinese | English

Product Center

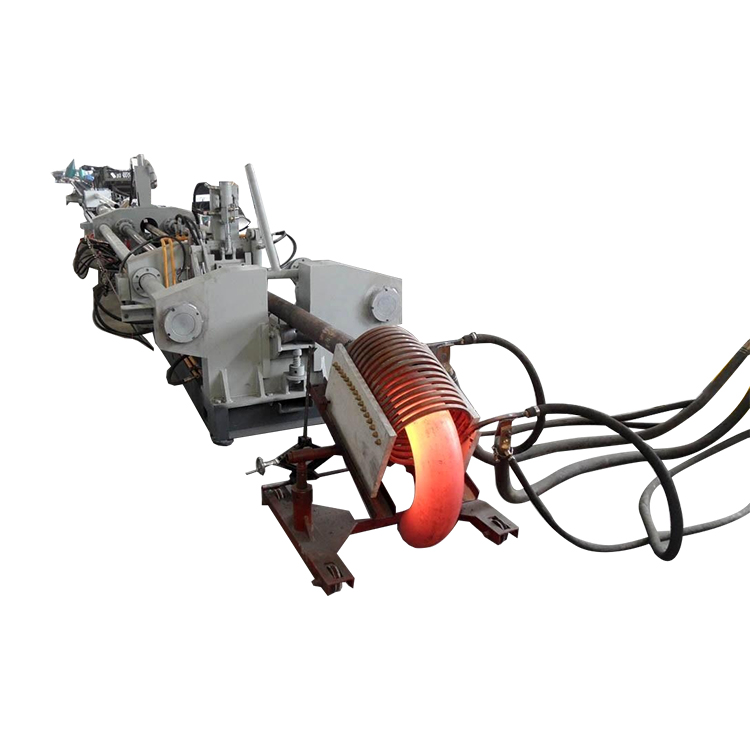

HOT FORMING ELBOW MACHINE

Hot forming elbow bend machine

Mechanical parameters

Technical parameters(313314)

| Model |

|

|

|

|

|

|

|

| Processing range | 1"~6" | 3"~12" | 8"~24" | 16"~30" | 20"~36" | 30"~48" | 32"~56" |

| Max. wall thickness | Sch40 | ||||||

| Max. pressure | 31.5MPa | ||||||

| Working pressure | 25MPa | ||||||

| Working speed | 0~1000mm/min | ||||||

| Return speed | 1500~2000mm/min | ||||||

| Cylinder diameter | 125mm×2 | 180mm×2 | 300mm×2 | 320mm×2 | 360mm×2 | 280mm×4 | 320mm×4 |

| Cylinder stroke | 3000mm | 4000mm | 5000mm | 5000mm | 6000mm | 8000mm | 10000mm |

| Cylinder thrust | 30T×2 | 30T×2 | 175T×2 | 200T×2 | 250T×2 | 150T×4 | 200T×4 |

| Motor power | 18.5kW | 22.5kW | 37.5kW | 48kW | 56kW | 68kW | 80kW |

| IF power supply needed | 160kW | 250kW | 400kW | 500kW | 600kW | 800kW | 1000kW |

Mechanical video

Equipment details

Elbow Bend machine

1. Elbow bending machine is the traditional product of Aocheng Machinery Equipment Factory, which is mainly used to produce various elbows of 1D ~ 2.5D.

2. With the technical development of elbow forming machine by our factory, the elbow machine has been improved in all aspects.At present, the elbow machine produced by our factory has been integrated with ultra-short stress line and taper die expanding technology;Digital control if induction heating technology;No back pressure, low energy consumption hydraulic transmission technology in one.

3. Realized the hydraulic opening and closing of push plate gate, hydraulic clamping of raw material steel tube and other mechanization innovations, and combined with the factory's two-step push pipe machine innovation and development of the new patent, the development of four oil cylinder intermediate frequency elbow machine and other new products.

Elbow is an important part of piping system.At present the elbow is mainly made of straight steel pipe or steel plate, and the processing method is die forming.Most elbows need to be heated before forming, which makes them prone to plastic deformation.From the point of view of whether welding process is needed, elbow is divided into joint elbow and seamless elbow.Seamless elbow parts die pressing, pushing and so on.Forged elbow can be machined directly from the blank to the material.

The main power of the hot forming elbow machine is hydraulic cylinder, the heating mode is medium frequency heating (in addition to the use of coal furnace and natural gas heating), mainly used for carbon steel and alloy steel elbow forming.

Related equipment